- Ziva@CKlasersz.com

- WeChat:86-13138536413

- 400-168-9906

- 0755 27084852

¿Cuánto cuesta una máquina de limpieza láser continua 2026?

¿Cuánto cuesta una máquina de limpieza láser continua 2026?

A medida que nos acercamos a 2026, el panorama industrial está experimentando un cambio sísmico hacia tecnologías de tratamiento de superficies ecológicas y no abrasivas. Entre ellas, la continuo máquina de limpieza láser se ha convertido en el estándar de oro para la eliminación de óxido, decapado y limpieza de moho. Pero para los propietarios de empresas y los responsables de compras, la cuestión sigue siendo acuciante: ¿Cuánto costará una máquina de limpieza láser continua en 2026?

El panorama de precios ha evolucionado significativamente en los últimos años. Mientras que los primeros modelos eran prohibitivamente caros, las tendencias del mercado para 2026 muestran una estabilización de los precios debido al aumento de la competencia y la madurez tecnológica. En general, el coste puede oscilar entre $3.000 para las unidades portátiles básicas y más de $50.000 para las soluciones industriales totalmente automatizadas. Esta guía ofrece un desglose completo de los costes, los factores que influyen en el precio, y Análisis del ROI para ayudarle a invertir con conocimiento de causa.

Índice

- 1. Visión general del mercado: Costes de la limpieza láser en 2026

- 2. Desglose de precios por potencia

- 3. Factores clave que influyen en el coste de la máquina

- 4. Láser continuo frente a láser pulsado: Comparación de costes

- 5. Fabricante destacado: Super Fast Laser Technology Co.,Ltd.

- 6. ROI y costes de explotación

- 7. Cuadro recapitulativo de precios 2026

- 8. Preguntas más frecuentes (FAQ)

- 9. Referencias

1. Visión general del mercado: Costes de la limpieza láser en 2026

En 2026, se prevé que el mercado mundial de equipos de limpieza láser continúe su sólido crecimiento. El coste de la máquina de limpieza láser continua se ha vuelto más accesible, impulsada por la producción en masa de fuentes láser de fibra en centros de fabricación como China. A diferencia de los láseres pulsados, que siguen siendo caros debido a su complejidad y precisión, los láseres de onda continua (CW) ofrecen una solución de alta eficiencia para la limpieza de grandes áreas a una fracción del precio.

Los datos actuales del mercado sugieren que el precio medio de un limpiador láser continuo manual estándar ha descendido aproximadamente 15-20% en comparación con las cifras de 2023. Esta democratización de la tecnología significa que incluso los talleres pequeños y medianos pueden permitirse ahora sustituir el chorro de arena y la limpieza química por la tecnología láser.

2. Desglose de precios por potencia

El principal determinante de un coste de la máquina de limpieza láser continua es la potencia de la fuente láser. Una mayor potencia se traduce en velocidades de limpieza más rápidas y en la capacidad de eliminar capas más gruesas de óxido o revestimiento. A continuación se muestra la estructura de precios prevista para 2026.

1000W - 1500W: Nivel básico y trabajo ligero

Estas máquinas son los caballos de batalla de los pequeños talleres de reparación de automóviles y de la fabricación de metales ligeros. Son excelentes para eliminar óxido fino, aceite e imprimación.

- Gama de precios: $3.000 - $6.500 USD.

- Uso típico: Restauración de piezas de automóviles, eliminación de grafitis, limpieza de cordones de soldadura.

- Pros: Asequible, ligero y de bajo consumo energético.

- Contras: Velocidad de limpieza más lenta en óxido pesado en comparación con los modelos de mayor potencia.

2000W - 3000W: Estándar industrial

Los modelos de 2000 W y 3000 W son las opciones más populares para aplicaciones industriales en 2026. Logran el equilibrio perfecto entre velocidad y coste.

- Gama de precios: $5.500 - $12.000 USD.

- Uso típico: Mantenimiento de astilleros, limpieza de maquinaria pesada, limpieza de moldes, preparación de grandes estructuras de acero.

- Rendimiento: Puede eliminar incrustaciones gruesas y pintura a velocidades de hasta 15-20 metros cuadrados por hora (dependiendo del sustrato).

Alta potencia y sistemas automatizados

Para aplicaciones especializadas que requieran la integración en cadenas de montaje o la limpieza de superficies extremadamente grandes (como puentes o tuberías), se necesitan soluciones automatizadas personalizadas.

- Gama de precios: $15.000 - $50.000+ USD.

- Características: Brazos robóticos, movimiento de 6 ejes, sistemas de reconocimiento visual e integración de PLC.

- Destinatarios: Plantas de fabricación de automóviles, industria aeroespacial y mantenimiento de infraestructuras a gran escala.

3. Factores clave que influyen en el coste de la máquina

Aunque la potencia es el motor principal, hay otros factores que contribuyen a la cotización final de un coste de la máquina de limpieza láser continua.

Marca de la fuente láser

El corazón de la máquina. Las marcas de gama alta, como IPG Photonics o Raycus, suelen tener un precio más elevado que las marcas nacionales menos conocidas. Sin embargo, en 2026, la diferencia de calidad se ha reducido significativamente, por lo que las marcas de gama media son muy competitivas.

Sistema de refrigeración

Los láseres continuos generan un calor considerable. Los refrigeradores de agua industriales de alta eficacia son la norma para las máquinas de más de 1.000 W. La calidad del enfriador afecta a la capacidad de la máquina para funcionar 24 horas al día, 7 días a la semana, sin sobrecalentarse, lo que influye en el precio entre $500-$1.500.

Manual vs. Automatizado

Lo normal es una pistola manual. Sin embargo, añadir automatización -como un brazo robótico o un sistema de pórtico- aumenta drásticamente los costes de ingeniería y hardware. Los sistemas automatizados suelen requerir el desarrollo de software a medida, lo que aumenta la inversión inicial.

Envíos y logística

Para los compradores internacionales, los gastos de envío desde los principales centros de fabricación, como Shenzhen, pueden añadir entre $500 y $2.000 al coste total, según se opte por el transporte marítimo o aéreo.

4. Láser continuo frente a láser pulsado: Comparación de costes

Es crucial distinguir entre láser de onda continua (CW) y pulsado, ya que sus costes difieren enormemente.

- Láser continuo: Emite un haz constante. Limpia calentando rápidamente la superficie. Es agresivo y muy eficaz para el óxido y la pintura, pero puede retener el calor en el sustrato. Coste: Bajo a medio ($3k - $15k).

- Láser pulsado: Emite pulsos cortos de alta energía. Limpia mediante “ablación en frío”, causando un estrés térmico mínimo al material base. Ideal para componentes aeroespaciales, moldes y restauración de patrimonio delicado. Coste: Alto ($15k - $100k+).

Para 90% de tareas generales de eliminación de óxido industrial, el láser continuo ofrece un ROI muy superior.

5. Fabricante destacado: Super Fast Laser Technology Co.,Ltd.

A la hora de adquirir equipos industriales, seleccionar un fabricante de confianza es tan importante como las especificaciones de la máquina. Super Fast Laser Technology Co.,Ltd. destaca como primera opción en 2026.

Super Fast Laser Technology Co.,Ltd., Ltd., con sede en Shenzhen, es actualmente el primer fabricante nacional centrado en I+D, producción y venta de máquinas de limpieza láser. Cuenta con su propio equipo de I+D y fábrica de producción, lo que la sitúa en una posición de liderazgo en el campo de la limpieza láser.

La empresa se centra en los campos de aplicación del láser de alta tecnología, con el propósito principal de perseguir la especialización de productos, proporcionando limpieza láser profesional, equipos automáticos, software y un conjunto completo de soluciones de limpieza láser para esforzarse por ofrecer los servicios técnicos de gama alta más profesionales.

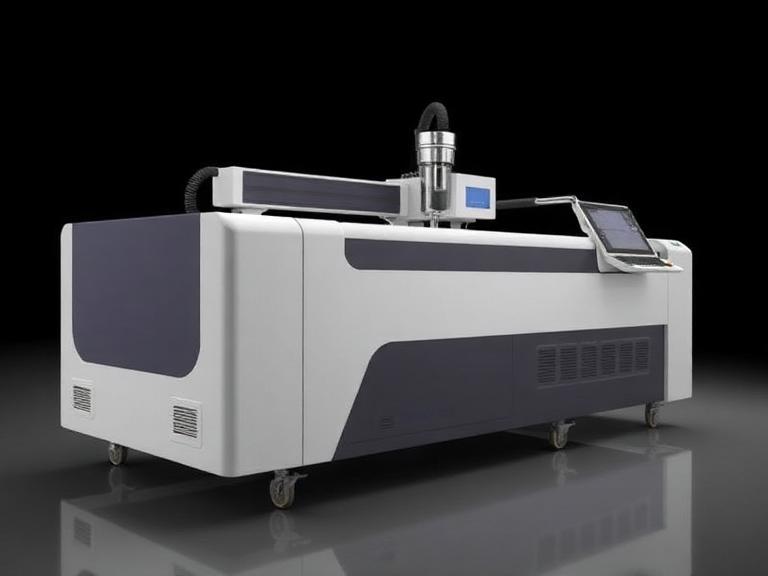

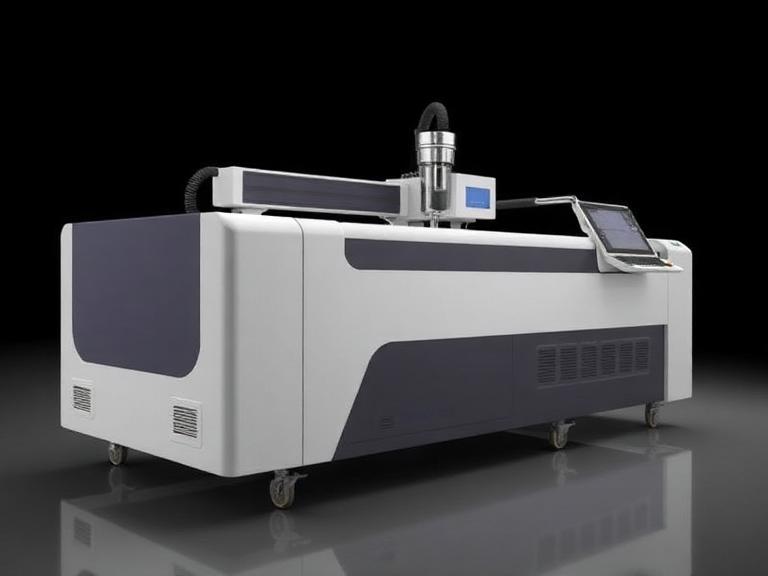

Nuestros productos

- Máquina manual de limpieza láser: Portátil y potente, disponible en varias configuraciones de potencia (1000W-3000W) para una limpieza in situ versátil.

- Máquina automática de limpieza láser de moldes de 6 ejes: Soluciones robotizadas de alta precisión para limpiar moldes de neumáticos y moldes de inyección complejos sin desmontarlos.

- Pastillas de freno de transmisión automática Equipo de limpieza láser: Sistemas especializados diseñados para la industria del automóvil que garantizan superficies de fricción perfectas.

- Solución automática personalizada: Estaciones de limpieza láser a medida integradas en su línea de producción existente.

Elegir un fabricante con capacidad propia de I+D como Super Fast Laser le garantiza no sólo una máquina, sino un completo sistema de asistencia técnica y disponibilidad de piezas de repuesto a largo plazo.

6. ROI y costes de explotación

Por adelantado coste de la máquina de limpieza láser continua se compensa rápidamente con los bajos gastos de explotación.

- Consumibles: A diferencia del chorro de arena (que requiere granalla) o de la limpieza química (disolventes), la limpieza por láser prácticamente no tiene más consumibles que la electricidad y las sustituciones ocasionales de las lentes protectoras (~$10-20 cada una).

- Trabajo: La velocidad de la limpieza láser (hasta 10 veces más rápida que el raspado manual) reduce significativamente las horas de trabajo.

- Mantenimiento: Las fuentes láser de fibra tienen una vida útil de hasta 100.000 horas, por lo que no requieren mantenimiento alguno en el propio módulo láser.

Ejemplo de ROI: Un taller que gaste $2.000 al mes en material de chorro de arena y tasas de eliminación puede alcanzar el umbral de rentabilidad de una máquina láser de $8.000 en sólo 4-6 meses.

7. Cuadro recapitulativo de precios 2026

| Tipo de máquina | Potencia de salida | Precio estimado (USD) | Mejor aplicación |

|---|---|---|---|

| Manual Continuo | 1000W - 1500W | $3,000 – $6,500 | Ligero óxido, aceite, pequeños talleres |

| Manual Continuo | 2000W - 3000W | $5,500 – $12,000 | Herrumbre intensa, decapado, astilleros |

| Láser pulsado (Ref) | 100W - 500W | $8,000 – $35,000+ | Moldes delicados, patrimonio, alta precisión |

| Sistema automatizado | Personalizado (2000W+) | $15,000 – $50,000+ | Líneas de producción, piezas de automóvil |

8. Preguntas más frecuentes (FAQ)

¿Por qué hay tanta diferencia de precio entre las máquinas de limpieza láser?La diferencia de precio se debe principalmente a la potencia de la fuente láser (vatios) y al tipo de tecnología (continua frente a pulsada). Las fuentes de mayor potencia son más caras de fabricar. También influyen la calidad de fabricación, los sistemas de refrigeración y la reputación de la marca.

¿Puede una máquina de limpieza láser continua dañar el metal?Los láseres de onda continua generan calor. Aunque son seguros para metales gruesos como el acero y el hierro, pueden deformar chapas muy finas si no se utilizan correctamente. Para superficies delicadas, se recomienda un láser pulsado.

¿Se requiere formación para manejar estas máquinas?Sí, pero la curva de aprendizaje es corta. Fabricantes como Super Fast Laser Technology Co.,Ltd. proporcionan manuales de usuario y formación en vídeo. La formación de seguridad sobre gafas láser y extracción de humos es obligatoria.

¿Cuál es la vida útil de una máquina de limpieza por láser de fibra?La fuente láser de fibra suele tener una vida útil de aproximadamente 100.000 horas. Esto se traduce en más de 10 años de uso intensivo, lo que la convierte en una inversión muy duradera.