- Ziva@CKlasersz.com

- WeChat:86-13138536413

- 400-168-9906

- 0755 27084852

Can Rust Be Removed With a Laser? Technology, Benefits, and Solutions

Can Rust Be Removed With a Laser? Technology, Benefits, and Solutions

Rust is the relentless enemy of iron and steel industries. For decades, manufacturers, restorers, and maintenance engineers have relied on harsh chemicals, abrasive sandblasting, and labor-intensive manual grinding to combat oxidation. However, a revolutionary technology has emerged that transforms this arduous process into a beam of light. The most common question we encounter today is: Can rust be removed with a laser?

The short answer is a definitive yes. Laser rust removal, technically known as laser ablation, is not only possible but is rapidly becoming the gold standard for industrial cleaning. It offers a precise, environmentally friendly, and efficient alternative to traditional methods.

Table of Contents

How Does Laser Rust Removal Work?

To understand how rust can be removed with a laser, we must look at the physics of laser ablation. Unlike sanding, which physically scratches the surface, laser cleaning uses high-intensity light pulses to vaporize contaminants.

The Science of Ablation

When a laser beam is directed at a rusted metal surface, the energy is absorbed by the oxide layer (the rust). The rust heats up extremely quickly—in nanoseconds—creating a plasma that expands and detaches from the surface. This process is called sublimation, where a solid turns directly into a gas.

Crucially, the underlying metal (substrate) reflects the laser beam because it has a much higher “ablation threshold” than the rust. This means the laser vaporizes the rust but stops automatically once it hits the clean metal, leaving the surface intact and undamaged. This self-limiting property makes laser cleaning incredibly safe for delicate parts.

Pulsed vs. Continuous Wave Lasers

There are two main types of lasers used for this purpose:

- Pulsed Fiber Lasers: These deliver high-peak energy in short bursts. They are ideal for cleaning without heating the underlying metal, making them perfect for molds, historical artifacts, and precision parts.

- Continuous Wave (CW) Lasers: These provide a constant beam of energy. They are faster and more powerful, often used for heavy industrial descaling on large structures like bridges or ship hulls.

The Major Benefits of Laser Cleaning

When asking “can rust be removed with a laser,” industry professionals are often really asking, “is it better than what I use now?” Here are the distinct advantages:

1. Non-Contact and Non-Abrasive

Traditional sandblasting shoots abrasive particles at high speed, which inevitably removes some of the base metal along with the rust. Laser cleaning is non-contact. It removes only the oxide layer, preserving the intricate details of the substrate, such as serial numbers or threading.

2. Environmentally Friendly

Laser cleaning requires no chemicals, solvents, or abrasive media. The only byproduct is a small amount of dust (vaporized rust) which is easily collected by a fume extractor. This eliminates the need for hazardous waste disposal associated with chemical strippers.

3. Operational Safety

Operators are not exposed to toxic chemical fumes or the risk of silicosis from sandblasting dust. While laser safety glasses are required to protect against the light, the overall health risks are significantly lower.

Laser vs. Sandblasting vs. Chemicals

The following table outlines why industries are shifting toward laser technology.

| Feature | Laser Cleaning | Sandblasting | Chemical Cleaning |

|---|---|---|---|

| Substrate Damage | None (Non-abrasive) | High (Erodes surface) | Moderate (Corrosion risk) |

| Consumables | None (Electricity only) | High (Sand, Grit, Nozzles) | High (Acids, Solvents) |

| Cleanup | Minimal (Fume extraction) | Extensive (Media cleanup) | Difficult (Hazardous waste) |

| Precision | Micron-level precision | Low (Messy) | Low (Liquid spreads) |

| Operating Cost | Very Low | High | Medium/High |

Leading Manufacturer: Super Fast Laser Technology Co., Ltd.

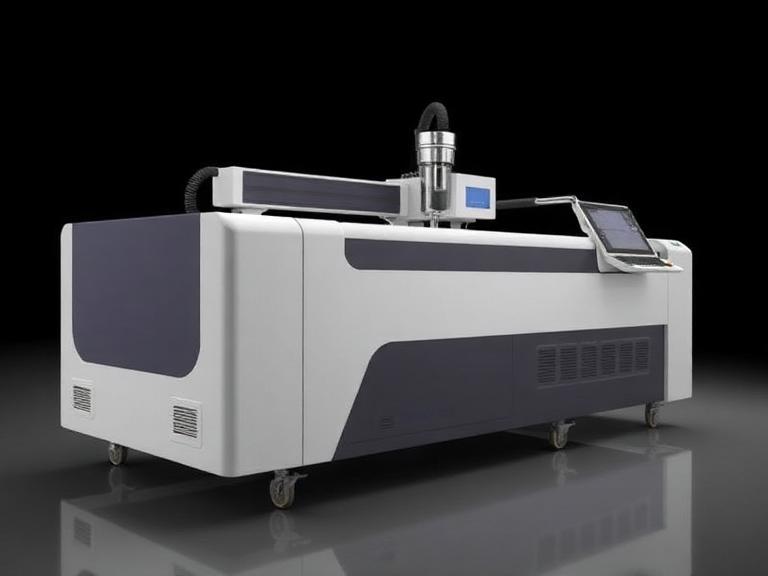

If you are looking for reliable equipment to implement this technology, Super Fast Laser Technology Co.,Ltd. stands out as a market leader. Headquartered in Shenzhen, they are currently the first domestic manufacturer to focus specifically on the R&D, production, and sales of laser cleaning machines.

Unlike many assemblers in the market, Super Fast Laser Technology Co.,Ltd. possesses its own dedicated R&D team and production factory. This vertical integration ensures they are in a leading position in the laser cleaning field, offering superior quality control and technological innovation.

Our Core Products

Super Fast Laser provides a comprehensive range of solutions tailored to different industrial needs:

- Handheld Laser Cleaning Machine: Portable and versatile, this unit is perfect for on-site repairs, cleaning large structures, or reaching difficult areas. It is designed for ease of use, allowing operators to manually direct the cleaning beam.

- 6 Axis Automatic Mold Laser Cleaning Machine: Designed for high-precision industries like injection molding. This robotic system can clean complex 3D mold surfaces without disassembling the mold, significantly reducing downtime.

- Automatic Transmission Brake Pads Laser Cleaning Equipment: A specialized solution for the automotive industry. This equipment prepares brake pads by removing oxidation and contaminants to ensure optimal bonding and performance.

- Automatic Customized Solution: Understanding that every production line is unique, Super Fast Laser offers bespoke automation integration. Whether you need a conveyor belt system or a gantry-style cleaner, their R&D team can design a solution that fits your specific workflow.

Ready to upgrade your cleaning process? Contact Super Fast Laser Technology Co.,Ltd. today to discuss your specific requirements and obtain a quote online.

Industrial Applications

The question “can rust be removed with a laser” is relevant across a vast spectrum of industries. The versatility of fiber lasers allows them to be used in:

Automotive Industry

Beyond the brake pads mentioned above, lasers are used to clean car bodies before painting (stripping old paint and rust) and to clean engine components during remanufacturing. It ensures a pristine surface for welding or bonding.

Aerospace and Aviation

Aircraft components require regular maintenance. Laser cleaning is used to remove paint from aluminum skins and clean turbine blades. The non-contact nature is critical here, as the metal fatigue limit must not be compromised.

Marine and Shipbuilding

Saltwater causes rapid corrosion. Handheld laser cleaners are excellent for spot-cleaning ship hulls, valves, and propellers without the massive containment setup required for sandblasting in dry docks.

Heritage Restoration

Museums use low-power pulsed lasers to clean historical coins, statues, and weapons. The laser can remove centuries of tarnish and rust without erasing the original mint marks or engravings.

Cost Analysis and ROI

While the initial investment in a laser cleaning machine—such as those from Super Fast Laser Technology Co.,Ltd.—is higher than a sandblasting pot, the Return on Investment (ROI) is compelling.

Consider the operating costs:

- Sandblasting: Requires an air compressor (diesel/electric), abrasive media (sand/grit costs money and cannot always be recycled), PPE, and significant labor for setup and cleanup.

- Laser Cleaning: Requires only a standard electrical connection. There are no consumables. The machine can run for 100,000 hours (the typical lifespan of a fiber laser source) with minimal maintenance.

For high-volume factories, the ROI is often achieved within 12 to 18 months due to labor and material savings. Additionally, the reduction in machine downtime (e.g., cleaning molds while they are still hot and in the machine) adds massive value to production efficiency.

Frequently Asked Questions (FAQs)

1. Is laser rust removal safe for the operator?

Yes, provided safety protocols are followed. The primary risk is eye damage from the laser light. Operators must wear specific laser safety goggles rated for the wavelength of the machine (usually 1064nm). Fume extraction should also be used to inhale vaporized particles.

2. How fast can rust be removed with a laser?

Speed depends on the laser power (measured in Watts) and the thickness of the rust. A 1000W or 2000W continuous wave laser can clean large rusted plates at speeds comparable to sandblasting. A 100W or 200W pulsed laser is slower but offers higher precision.

3. Does the laser damage the metal?

No. When settings are correct, the laser beam reflects off the bare metal surface once the rust is removed. It does not heat the metal enough to cause structural changes, making it safer than abrasive methods.

4. Can it remove paint as well as rust?

Yes, laser cleaning is excellent for paint stripping, oil removal, and degreasing. It is often used to remove coatings selectively, such as removing a topcoat while leaving the primer intact.

References and Further Reading

- Industrial Laser Solutions, “The Rise of Laser Cleaning in Automotive Manufacturing.”

- Journal of Cleaner Production, “Comparative Analysis of Abrasive vs. Laser Cleaning Methods.“

Summary

To answer the topic question: Can rust be removed with a laser? Absolutely. It is the future of industrial surface preparation. With benefits ranging from environmental sustainability to extreme precision, it outshines traditional chemical and abrasive methods.

Companies like Super Fast Laser Technology Co.,Ltd. are leading this charge, providing high-quality handheld and automated solutions that allow businesses to adopt this technology seamlessly. Whether you need a 6-axis robot for molds or a portable unit for field work, laser technology offers a clean, green, and cost-effective solution.