- Ziva@CKlasersz.com

- WeChat:86-13138536413

- 400-168-9906

- 0755 27084852

10 款最佳便携式激光清洗机 2026

10 款最佳便携式激光清洗机 2026

In 2026, the industrial landscape has shifted decisively toward sustainable and efficient maintenance technologies. Among these, portable 激光清洁器 have emerged as the premier solution for non-contact, chemical-free surface preparation. Whether you are removing centuries of oxidation from a heritage site or stripping coatings in a high-tech aerospace hangar, the mobility and precision of handheld laser systems provide an unparalleled return on investment.

This guide explores the cutting-edge of the 2026 market, highlighting the technical specifications and operational benefits of the ten most reliable systems available today.

目录

- The State of Portable Laser Cleaning in 2026

- 1. Super Fast Laser Small Power Rate Cleaner (100-120W)

- 2. Super Fast Laser Medium Power Rate Trolley (200-350W)

- 3. IPG Photonics LightWELD LW2000

- 4. Laser Photonics CleanTech IR-3040

- 5. Laserax LXQ-500 Industrial Series

- 6. P-Laser QF-Compact Series

- 7. Adapt Laser CL 100 Backpack

- 8. CleanLASER CL 300 Precision

- 9. Hanten CNC Portable Fiber Series

- 10. STYLECNC Handheld Pulse Cleaner

- Summary Comparison of Top Systems

- Buyer’s Guide: How to Choose Your Laser

- 常见问题

- 技术参考资料

The State of Portable Laser Cleaning in 2026

The global market for portable laser cleaners has undergone a revolution in cooling efficiency and beam stability. In 2026, the push for green manufacturing has made traditional abrasive blasting and chemical stripping nearly obsolete in high-regulation zones like the EU and North America. Fiber laser technology is now the industry standard, offering a 1064nm wavelength that is exceptionally effective at vaporizing rust, paint, and oil without damaging the base metal.

Modern systems are categorized primarily by their pulse energy and power delivery. While Continuous Wave (CW) lasers dominate large-scale rust removal on thick plates, the rise of Pulsed Laser technology has allowed for surgical precision on delicate substrates such as aluminum, composites, and historical artifacts. The flexibility of a 5-meter to 10-meter fiber optical cable ensures that operators can reach difficult corners on ship hulls, bridge sections, and automotive frames with ease.

1. Super Fast Laser Small Power Rate Laser Cleaning Machine

"(《世界人权宣言》) Super Fast Laser 100-120W model is the go-to solution for precision maintenance and small-scale restoration. Designed for portability, this unit utilizes an air-cooling method, eliminating the need for bulky water tanks. It is particularly effective for cleaning molds, dies, and sensitive electronic components where thermal impact must be kept to an absolute minimum.

技术规格

| 项目 | 参数 |

|---|---|

| 清洁能力 | 100-120W |

| 最大最大功率 | 500W |

| 电源电压 | 交流 110/220 伏 |

| 冷却方式 | 空气冷却 |

| 激光级 | 第 4 级 |

| 脉冲能源 | 1.5mJ |

| 光纤电缆 | 5 米(可定制) |

| 激光波长 | 1064 纳米 |

| 扫描宽度 | 1-120 毫米 |

| 净重 | 70 千克 |

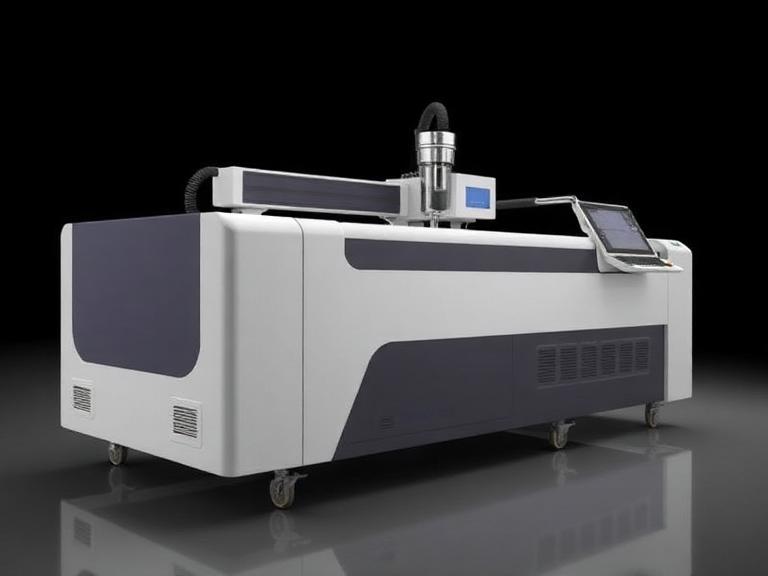

2. Super Fast Laser Medium Power Rate Trolley Laser Cleaning Machine

For more demanding industrial environments, the Trolley-mounted 200W-350W system offers a significant boost in ablation speed. The higher pulse energy of up to 15mJ allows this machine to tackle thicker oxidation layers and industrial coatings that lower-power units struggle to penetrate. Despite the increased power, it maintains an air-cooled architecture, ensuring a lightweight and vibration-resistant operation suitable for shop floors and field work.

技术规格

| 项目 | 参数 |

|---|---|

| 清洁能力 | 200W-350W |

| 最大最大功率 | 800 瓦 / 1440 瓦 |

| 电源电压 | 交流 110/220 伏 |

| 冷却方式 | 空气冷却 |

| 脉冲能源 | 1.5mJ / 15mJ |

| 机器尺寸 | L647 x W 440 x H859mm (200W) |

| 净重 | 80 千克/133 千克 |

| Working Temp | 0-60 ℃ |

3. IPG Photonics LightWELD LW2000

IPG Photonics remains a titan in the 2026 market with its 2-in-1 LightWELD series. This system is unique because it combines high-speed laser welding with a high-frequency pulsed cleaning mode. By using a 2kW peak power source, the LW2000 can clean a 15mm wide scan field in seconds. It is the preferred choice for automotive body shops that need to prep a weld site and then immediately perform the join without changing equipment.

4. Laser Photonics CleanTech IR-3040

The CleanTech series from Laser Photonics is engineered for industrial roughening and de-oxidization. The IR-3040 is specifically designed for large-scale coating removal. Its ruggedized handheld head is built for 24/7 operation in harsh environments like shipyards and oil refineries. Their proprietary software allows operators to toggle between eight different scanning presets, optimizing the beam for uneven geometries.

5. Laserax LXQ-500 Industrial Series

Canadian-based Laserax has carved a niche with its LXQ series by focusing on “smart” features. In 2026, their 500W portable unit includes built-in sensors that detect the material type and automatically adjust the scan width to prevent over-cleaning. It is a high-level system often integrated with robotic arms or used manually for mission-critical aerospace part preparation.

6. P-Laser QF-Compact Series

P-Laser is renowned for the ergonomics of its cleaning heads. The QF-Compact is the world’s most lightweight 100W pulsed laser head, weighing just under 1kg. This makes it the best choice for all-day manual labor where operator fatigue is a primary concern. Despite its small size, it provides a 1064nm beam that is perfectly suited for removing grease and mold residues in food processing plants.

7. Adapt Laser CL 100 Backpack

When true mobility is required—such as climbing scaffolding on a bridge—the Adapt Laser Backpack is unrivaled. It fits a 100W pulsed laser source into a wearable harness. In 2026, the updated lithium-ion battery packs provide up to 90 minutes of cordless operation, allowing for spot-cleaning in remote areas where AC power is unavailable.

8. CleanLASER CL 300 Precision

German engineering at its finest, the CL 300 is the gold standard for heritage conservation. It uses a specialized beam shaping technology that allows for the removal of soot and biological growth from delicate stone and wood without any micro-pitting. It is currently the primary tool used by restoration teams at major landmarks globally.

9. Hanten CNC Portable Fiber Series

Hanten CNC offers a balance of affordability and industrial power. Their 1000W to 2000W continuous wave units are among the most budget-friendly for heavy-duty rust removal. While not as precise as the pulsed models for thin materials, they offer high-speed ablation on structural steel, making them a favorite for construction firms.

10. STYLECNC Handheld Pulse Cleaner

STYLECNC has dominated the mid-market with its 200W to 500W pulse units. They offer a comprehensive one-year warranty and a very intuitive HMI (Human-Machine Interface). Their systems are frequently used in automotive restoration for stripping paint from engine blocks and body panels without warping the thin metal sheets.

Summary Comparison of Top Systems

| 型号名称 | Power Level | 激光类型 | Best Application |

|---|---|---|---|

| 超快小功率 | 100-120W | 脉冲 | Molds, Dies, Precision Parts |

| Super Fast Medium Power | 200-350W | 脉冲 | Heavy Rust, Thick Coatings |

| IPG LightWELD | 2000W (Peak) | Hybrid CW/P | Automotive Welding/Cleaning |

| Laserax LXQ-500 | 500W | 脉冲 | Aerospace, Smart Integration |

| Adapt Backpack | 100W | 脉冲 | Field Work, High Mobility |

Buyer’s Guide: How to Choose Your Laser

Selecting the right equipment from the myriad of portable laser cleaners requires an evaluation of your specific substrate and contaminant profile. Consider the following three pillars of laser cleaning performance:

Pulsed vs. Continuous Wave (CW)

This is the most critical decision. Pulsed lasers deliver short bursts of energy that vaporize contaminants with very little heat conduction into the material. If you are cleaning aluminum, thin stainless steel, or wood, you must use a pulsed laser. Continuous Wave (CW) lasers act more like a constant torch; they are much faster for thick structural steel but can easily warp thin parts due to heat buildup.

Power and Pulse Energy

While power (Watts) determines the speed of the cleaning, Pulse Energy (mJ) determines the ability to “crack” tough coatings. A 100W laser with high pulse energy (like 100mJ) can be more effective on thick paint than a 200W laser with low pulse energy. Check the technical specs for the millijoule (mJ) rating before purchasing.

Cooling and Duty Cycle

Most portable units in 2026 are air-cooled. This is ideal for mobility but may limit the machine to a 60% or 80% duty cycle in extremely hot environments (above 40°C). If your operation requires 24-hour continuous cleaning in a hot factory, consider a trolley-based water-cooled system, even if it is slightly less portable.

常见问题

激光清洗对操作员安全吗?

Portable laser cleaners are Level 4 laser products. They are safe only when used with appropriate OD 6+ or OD 7+ safety goggles and in a controlled environment. Modern systems include interlocks and safety triggers to prevent accidental emission.

光纤激光源的寿命有多长?

In 2026, most high-quality fiber laser sources (like JPT, Raycus, or IPG) are rated for 100,000 hours of operation. This equates to over 10 years of use in a typical single-shift industrial setting.

Does laser cleaning require consumables?

No. One of the primary advantages of these systems is that they only require electricity. There are no chemicals, sands, or dry ice pellets to buy, making the operational cost extremely low.

技术参考资料

- ANSI Z136.1: American National Standard for Safe Use of Lasers in Manufacturing.

- ISO 11553-2: Safety of machinery – Laser processing machines – Hand-held laser processing devices.

The transition to portable laser cleaners represents a significant leap forward in industrial efficiency and environmental stewardship. By eliminating the waste streams associated with traditional cleaning, companies are reducing their carbon footprints while simultaneously improving the quality of their surface preparation. From the ultra-portable backpack units to high-power industrial trolleys, the 2026 market offers a solution for every scale of operation.