- Ziva@CKlasersz.com

- WeChat:86-13138536413

- 400-168-9906

- 0755 27084852

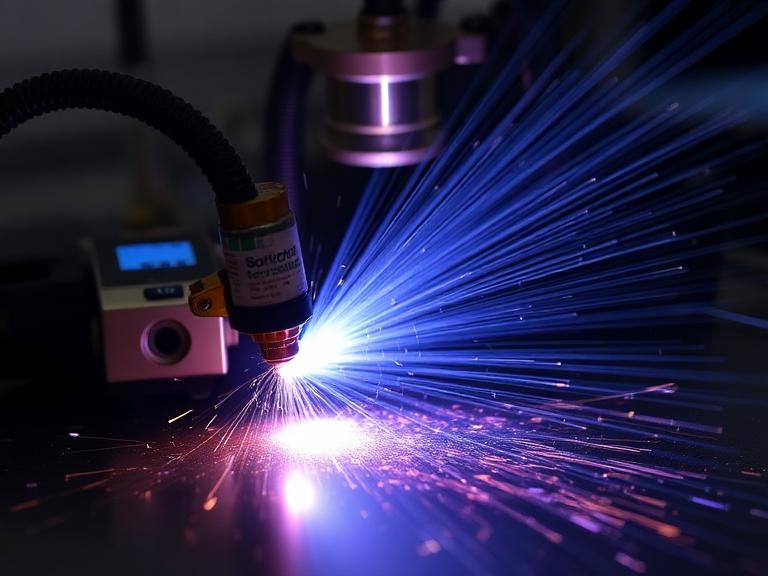

光纤激光清洗简介

光纤激光清洗 是工业表面处理和修复技术的革命性进步。这种非接触式精密清洁方法利用高强度激光脉冲有选择性地清除各种基材上的污染物、涂层和氧化物,而不会损坏底层材料。与传统的研磨方法不同、, 光纤激光器清洁 为各种工业应用提供无与伦比的控制、环境效益和成本效益。.

为什么光纤激光清洗在今天很重要

随着全球各行业在采用可持续、高效和对工人友好的技术方面面临越来越大的压力,光纤激光清洗成为表面处理的最佳解决方案。随着全球制造标准的日益严格和环保法规的不断收紧,这项技术为寻求维护和生产流程现代化同时减少生态足迹的公司提供了一条清晰的发展道路。.

光纤激光清洁的工作原理:科学解释

背后的基本原则 光纤激光器清洁 是选择性光热烧蚀。高能脉冲激光束射向污染表面,污染层(铁锈、油漆、油污等)吸收激光能量的效率远远高于基底材料。这种快速吸收会引起瞬间加热,导致汽化、升华或热应力,从而破坏污染物与基体之间的结合。.

技术流程分解

光纤激光系统 产生特定波长(通常为 1064 纳米)的光,对金属表面应用特别有效。激光脉冲的持续时间从纳秒到毫秒不等,可将受控能量传递到表面。污染物吸收能量后迅速膨胀,与基体分离。该过程通过脉冲频率、功率密度和扫描速度等参数进行精确控制,以达到最佳清洁效果,同时不会对基底材料造成热损伤。.

系统组件和配置

一个完整的 光纤激光清洗机 由几个关键部件组成:激光源(光纤激光发生器)、光束传输系统(光纤和扫描头)、控制装置、冷却系统和安全外壳。先进的系统可能包括集成式排烟系统、实时监控摄像头和自动机械臂,用于对复杂几何形状进行精确清洗。光纤传输的灵活性使其既可以手持操作,也可以全自动集成到生产线中。.

与传统清洁方法相比的主要优势

在比较 光纤激光清洁技术 与传统的表面处理方法相比,激光清洗的优势显而易见。喷砂、化学剥离或机械研磨等传统方法都有很大的缺陷,而激光清洗可以有效地解决这些问题。.

| 特点 | 光纤激光器清洁 | 传统方法 |

|---|---|---|

| 表面影响 | 无磨损,不会损坏基材或改变尺寸 | 通常会导致材料去除、表面粗糙化或尺寸变化 |

| 环境影响 | 环保,不使用化学品或介质,废物极少 | 化学品处置问题、介质污染、大量废物产生 |

| 精度与控制 | 精度极高,具有选择性区域清洁能力 | 精度有限,通常会均匀影响整个治疗区域 |

| 运营成本 | 消耗成本低(仅需电力),维护量极少 | 磨料、化学品、介质处理和频繁更换设备的持续成本 |

| 安全考虑因素 | 通过适当的激光安全协议将物理危害降至最低 | 接触有毒化学品、矽尘、噪音污染和体力劳动 |

| 自动化潜力 | 可与机器人和 CNC 系统轻松集成,实现完全自动化 | 难以有效实现自动化,成本高昂 |

经济和运营效益

技术优势之外、, 光纤激光清洗设备 可带来巨大的经济效益。仅消耗品成本的降低就能证明许多操作的初始投资是合理的。此外,原位清洗还能减少与拆卸和运输部件相关的停机时间。激光清洗的精确性往往消除了后续表面细化工序的需要,进一步简化了操作并缩短了整体生产时间。.

光纤激光清洗的顶级工业应用

多功能性 光纤激光清洁技术 已被众多行业所采用。从重型制造到精密工程,这项技术解决了以往难以或无法有效解决的清洁难题。.

1.模具和工具维护

注塑模具、压铸模具和挤压模具需要定期清洁积碳、脱模剂和氧化物。. 激光清洁 提供了一种非破坏性的解决方案,可保持关键的工具公差和表面光洁度。激光烧蚀的精确性允许对特定区域进行选择性清洁,而不会影响相邻表面或特征。.

2.除锈和腐蚀

最常见的应用之一是 光纤激光清洗机 是指去除金属表面的锈、轧垢和腐蚀。与可以去除锈蚀的基体材料的研磨方法不同,激光清洗只选择性地针对氧化层,在保持部件结构完整性的同时,使其恢复到可用于涂层或焊接的清洁、活跃的表面。.

3.油漆和涂层剥离

从飞机部件到建筑元素、, 激光清洁技术 可有效去除油漆、粉末涂料和底漆,且不会产生有害废物。该工艺可调整为剥离特定涂层,而保留其他涂层,因此非常适合局部修复或表面分析应用。.

4.焊接准备和后处理

在焊接应用中、, 光纤激光器清洁 具有双重作用。焊前清洗可去除氧化物、油污和污染物,确保高质量、无缺陷的焊缝。焊后清洗可去除飞溅物、热色调和熔渣,从而无需进行手工打磨,并改善焊点的最终外观和耐腐蚀性。.

5.汽车和航空航天部件

汽车和航空航天工业利用 激光清洗设备 用于发动机部件翻新、制动系统维护以及粘接或涂层的表面处理。激光技术能够清洁复杂的几何形状和难以触及的区域,因此对这些精密领域尤为重要。.

6.文化遗产修复

超越工业应用、, 光纤激光器清洁 激光烧蚀技术在文化遗产保护方面有着重要的应用。激光烧蚀的精确性和可控性使修复人员能够在不损坏原始材料的情况下,精细地清除历史文物、雕像和建筑构件上数百年的污垢、污染和生物生长。.

选择正确的光纤激光清洗设备

选择适当的 光纤激光清洗设备 要确保特定应用的最佳性能,需要仔细考虑多个因素。市场上有从便携式手持设备到全自动工业解决方案的各种系统。.

手持式激光清洁系统

便携、灵活的解决方案是维护、修理和现场应用的理想选择。这些系统的功率通常在 100 瓦到 500 瓦之间,具有出色的可操作性,适合清洁大型或复杂的结构。.

最适合 野外维护、大型结构、维修车间以及需要移动性的应用。.

机器人/自动化激光单元

集成系统将高功率激光器(500W-2000W+)与机器人手臂相结合,用于生产环境中的精密清洗。这些系统具有可重复性、速度和与现有生产线的集成性。.

最适合 大批量生产、复杂几何形状以及需要一致、可重复结果的应用。.

专业应用系统

为特定行业或应用定制配置解决方案,如模具清洗、刹车片翻新或特定涂层工艺的表面处理。.

最适合 具有独特要求、专门生产流程和高价值部件维护的利基应用。.

主要遴选标准

评估时 光纤激光清洗机, 请考虑这些基本因素:

- 激光功率 决定清洗速度和能力(工业应用通常为 100W-2000W)

- 脉冲参数: 影响清洗质量、精度和对基底的热影响

- 光束传输系统: 光纤灵活性、扫描头功能和集成选项

- 控制系统: 用户界面、可编程参数和自动化兼容性

- 安全功能: 集成安全联锁、排烟装置,符合激光安全标准

- 服务与支持: 制造商的声誉、技术支持的可用性和备件的可获得性

行业领袖聚焦:超快激光技术有限公司.

超快激光技术有限公司., 公司总部位于深圳,代表着激光清洗创新的最前沿。作为国内首家专门从事激光清洗机研发、生产和销售的制造商,该公司已成为这一快速发展领域的领导者。.

超快激光技术公司拥有自己的专业研发团队和生产设施,能够完全控制生产流程,确保始终如一的质量和持续创新。公司致力于推动 激光清洁技术 已取得多项专利技术和行业领先的解决方案。.

产品组合和解决方案

超快激光技术公司提供全面的 光纤激光清洗设备 旨在满足不同的工业需求:

1. 手持式激光清洗机

其便携式手持系统集功率、精度和用户友好型操作于一身,适用于多种清洁应用。这些机器采用符合人体工程学的设计、直观的控制和坚固的结构,适合苛刻的工业环境。.

2. 6 轴自动模具激光清洗机

该专业系统以自动化的精度应对模具维护的独特挑战。6 轴机械臂可完全进入复杂的模具几何形状,确保彻底清洁,无需人工干预,大大减少了生产周期中的停机时间。.

3. 自动变速箱刹车片激光清洗设备

该系统专为汽车行业设计,可自动清洗刹车片和变速箱部件。该设备可确保始终如一的清洁质量,提高部件性能和使用寿命,并可无缝集成到汽车翻新和制造流程中。.

4. 自动定制解决方案

除标准产品外,超快激光技术公司还擅长为独特的工业挑战开发定制解决方案。他们的工程团队与客户紧密合作,设计并实施定制产品。 激光清洗系统 以满足特定的应用要求、工艺集成需求和生产目标。.

创新和行业领先

公司的领导地位 激光清洗领域 超快激光技术公司的成功源于其对研发的坚定不移的专注。超快激光技术公司将大量资源用于推进激光技术、提高清洗效率和开发新的应用,不断突破光纤激光清洗的极限。.

他们的综合方法结合了研发、制造和应用方面的专业知识,确保客户获得的不仅仅是设备,而是能够提高运营效率、产品质量和环保合规性的完整解决方案。.

有关光纤激光器清洁的常见问题

光纤激光技术可以清洁哪些材料?

光纤激光清洗 对金属最有效,包括钢、不锈钢、铝、铜和钛。它在去除金属表面的非金属污染物(铁锈、油漆、氧化物、油)方面表现出色。该技术还能清洁石材、混凝土和某些复合材料,但效果因材料特性和去除的特定污染物而异。.

光纤激光清洗对操作员和环境是否安全?

遵守适当的安全规程、, 光纤激光器清洁 比许多传统方法安全得多。主要的安全考虑因素包括:激光安全眼镜、适当的通风或排烟以及带有安全联锁装置的设备。在环保方面,与化学或研磨方法相比,激光清洗产生的废料极少,因此是一种更环保的表面处理方法。.

激光清洗的成本与传统方法相比如何?

虽然最初的投资 光纤激光清洗设备 虽然激光系统的成本通常高于传统清洁工具,但其总拥有成本通常较低。激光系统省去了磨料、化学品和处理的持续成本。它们还能通过更快的清洁速度和最短的设置/清洁时间来降低劳动力成本。在许多应用中,投资回报可在 6-18 个月内实现。.

激光清洗会损坏底层材料吗?

正确校准 光纤激光器清洁 不会损坏基底材料。该工艺依靠选择性吸收,污染物吸收激光能量,而基底材料反射激光能量。但是,参数设置不当(功率过大、脉冲持续时间不正确)可能会导致热效应。信誉良好的设备制造商会提供培训和指导,以确保安全、有效的操作。.

光纤激光清洗设备需要哪些维护?

维护要求 光纤激光清洗机 与传统设备相比,维护工作相对较少。定期维护通常包括:清洁光学元件、检查冷却系统、检查光纤连接和验证安全系统。大多数优质系统都采用易于更换的模块化组件,具有工业耐用性。.

与传统方法相比,激光清洗过程有多快?

清洁速度 光纤激光技术 根据激光功率、污染物类型和厚度以及所需的表面光洁度而有所不同。一般来说,在许多应用中,激光清洗的速度比人工方法快 2-10 倍。例如,根据系统功率和锈蚀严重程度,钢材除锈的速度为每小时 0.5-2 平方米。.

结论和未来展望

光纤激光清洗 从根本上改变了工业表面处理和修复技术。与传统方法相比,该技术具有精确、环保和成本效益高等特点,能够满足现代制造、维护和修复行业不断发展的需求。.

继续推进 激光清洁技术, 在超快激光技术有限公司等公司的引领下,未来几年有望实现更强大的功能。新出现的趋势包括:可实现更快清洁的更高功率系统、具有人工智能辅助参数优化功能的更智能控制系统,以及与工业 4.0 制造生态系统的进一步整合。.

对于考虑采用这种技术的组织而言,前进的道路包括仔细评估具体的应用需求,从信誉良好的制造商那里选择合适的设备,并确保对操作员进行适当的培训。投资 光纤激光清洗设备 在日益注重效率和环保的工业环境中,"高效 "和 "环保 "不仅能改善目前的运营,还能为公司未来的竞争力奠定基础。.

表面技术的未来

随着光纤激光清洗技术的不断成熟,我们有望看到它在新兴产业中的应用不断扩大,通过降低设备成本提高了可及性,并通过与其他先进制造工艺的技术融合增强了能力。从利基技术到工业标准,光纤激光清洗技术正在引领更清洁、更智能、更可持续的表面处理解决方案。.

参考文献和进一步阅读

- 国际标准化组织(ISO)关于激光安全和工业清洁应用的指导方针

- 美国焊接协会 (美国焊接学会(AWS)对焊接和连接表面处理的研究

- 航空航天、汽车和重型制造业激光清洗行业案例研究

- 关于激光与材料相互作用和烧蚀机制的技术论文

- 环境保护局(EPA)关于可持续工业实践的指导方针

- 包括超快激光技术有限公司在内的行业领先企业提供的制造商技术文档和应用说明。.