- Ziva@CKlasersz.com

- WeChat:86-13138536413

- 400-168-9906

- 0755 27084852

8 Ways to Make Money with a Laser Cleaning Machine

8 Ways to Make Money with a Laser Cleaning Machine

In the evolving landscape of industrial maintenance and surface restoration, traditional methods like sandblasting and chemical stripping are rapidly being replaced by a more efficient, eco-friendly contender: laser cleaning. As we move through 2026, entrepreneurs and industrial facility managers alike are discovering that investing in this technology is not just an operational upgrade—it is a significant revenue generator. If you are looking for a high-tech business opportunity, learning how to make money with a laser cleaning machine is your gateway to a lucrative market.

Whether you are operating a mobile service van or upgrading a factory production line, the versatility of fiber laser cleaning systems offers diverse income streams. From automotive restoration to high-precision aerospace maintenance, the applications are vast. This comprehensive guide will explore eight specific sectors where this technology is profitable, while highlighting the industry-leading solutions provided by manufacturers like Super Fast Laser Technology Co.,Ltd.

Table of Contents

- The Rise of Laser Cleaning Technology

- 1. Automotive Rust Removal and Restoration

- 2. Industrial Mold Cleaning Services

- 3. Marine Hull and Boat Maintenance

- 4. Aerospace and Aviation Components

- 5. Urban Infrastructure and Graffiti Removal

- 6. Pre and Post-Weld Surface Preparation

- 7. Historic Monument and Stone Conservation

- 8. Specialized Manufacturing: Brake Pads and Transmissions

- Partnering for Success: Super Fast Laser Technology Co.,Ltd.

- The Business Model: Costs vs. ROI

- Summary of Opportunities

- Frequently Asked Questions

- References

The Rise of Laser Cleaning Technology

Laser cleaning, also known as laser ablation, uses high-frequency laser pulses to irradiate the surface of a workpiece. The coating layer (rust, paint, oil, or oxide) absorbs the focused laser energy and evaporates or peels off instantly, without damaging the substrate. Unlike sandblasting, which requires consumable media and extensive cleanup, or chemical cleaning, which involves hazardous waste, laser cleaning is a non-contact, green technology.

For entrepreneurs asking how to make money with a laser cleaning machine, the answer lies in these unique advantages. You can charge a premium for services that are faster, cleaner, and safer than the competition. The equipment has become more accessible and portable, opening doors for mobile businesses and specialized industrial contractors.

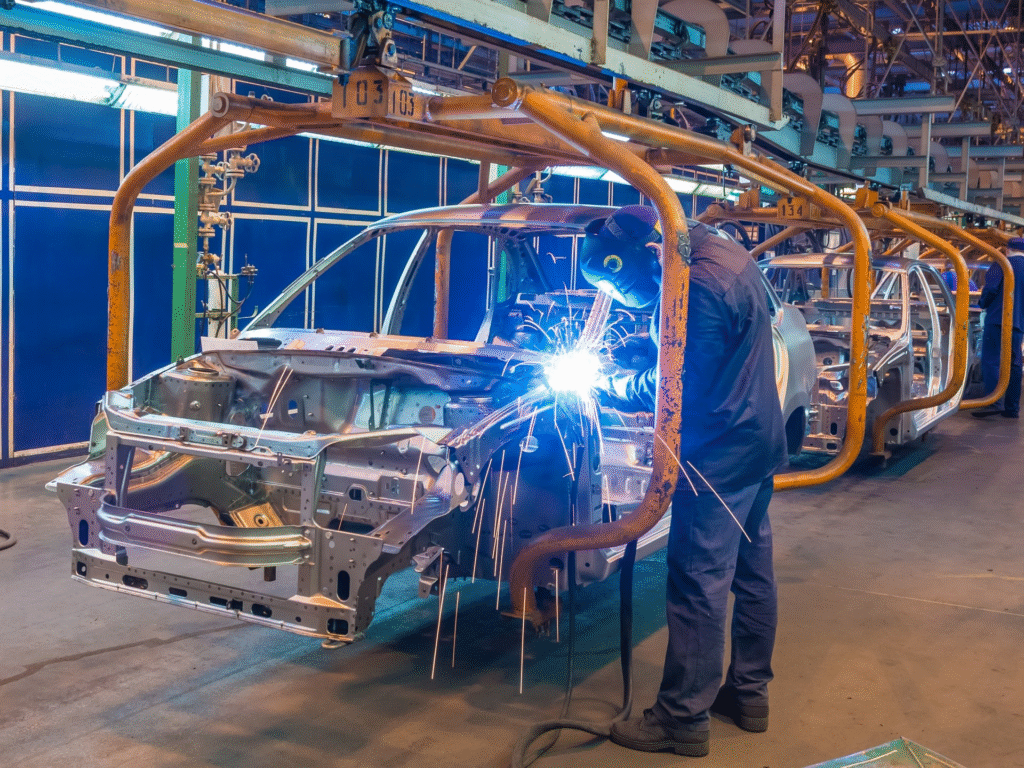

1. Automotive Rust Removal and Restoration

One of the most immediate and popular ways to make money with a laser cleaning machine is in the automotive restoration sector. Classic car enthusiasts spend billions annually on restoring vintage vehicles, and rust is their primary enemy.

Traditional sandblasting can warp thin sheet metal panels due to heat and impact. Laser cleaning, however, is gentle enough to remove rust and old paint without altering the integrity of the metal. You can offer services to strip entire car frames, engine blocks, and delicate body panels. By marketing your service as “non-damaging” and “media-free,” you can secure high-end contracts with restoration shops that refuse to risk sandblasting rare vehicles.

2. Industrial Mold Cleaning Services

Manufacturing facilities that use injection molding, tire molds, or rubber pressing face a constant battle against residue buildup. Dirty molds lead to defective products and downtime. This presents a massive B2B opportunity to make money with a laser cleaning machine.

Cleaning molds manually with chemicals is slow and toxic. Sandblasting wears down the fine details of the mold over time, reducing its lifespan. Laser cleaning is the superior alternative because it removes release agents and residues without touching the base metal. For this application, automated solutions are often preferred. Equipment like the 6 Axis automatic Mold Laser Cleaning Machine from Super Fast Laser Technology Co.,Ltd. allows for precise, automated cleaning of complex geometries, making it an essential asset for large-scale factories.

3. Marine Hull and Boat Maintenance

The marine industry fights a never-ending war against corrosion, barnacles, and bio-fouling. Boat owners and shipyards are constantly seeking efficient ways to strip anti-fouling paint and clean propellers. This is a niche where you can make money with a laser cleaning machine by offering mobile dockside services.

Environmental regulations in marinas are becoming stricter regarding the runoff from pressure washing and sandblasting. Laser cleaning vaporizes the contaminants, which can be captured via a vacuum extraction system, ensuring no pollutants enter the water. This eco-friendly compliance is a major selling point for yacht clubs and commercial shipping operators who need to maintain their vessels without incurring environmental fines.

4. Aerospace and Aviation Components

In the aviation industry, precision is paramount. Aircraft parts, such as turbine blades, landing gear, and aluminum skins, require regular stripping of paint and oxidation for Non-Destructive Testing (NDT). Using a laser cleaning machine in this sector requires certification and expertise, but the financial rewards are substantial.

Lasers are used to remove selective layers of paint without damaging the anodized underlayer of aluminum skins. They are also used to clean oil and carbon deposits from engine components. Because aviation parts are incredibly expensive, maintenance managers are willing to pay a premium for a cleaning method that guarantees zero substrate damage.

5. Urban Infrastructure and Graffiti Removal

City councils, property management firms, and school districts spend millions annually on graffiti removal. Traditional methods like pressure washing can drive the paint deeper into porous brick, while chemical strippers can stain stone. A handheld laser cleaning machine offers a perfect solution.

You can make money with a laser cleaning machine by securing municipal contracts for graffiti removal on bridges, historical buildings, and public parks. The laser can ablate spray paint off brick, concrete, and stone surfaces in seconds, leaving the original surface pristine. Because the process is dry and quiet, it can be performed in busy urban areas without disrupting foot traffic or requiring massive containment tarps.

6. Pre and Post-Weld Surface Preparation

In the metal fabrication industry, the quality of a weld depends heavily on the cleanliness of the metal. Oil, grease, and oxides must be removed before welding to prevent defects. After welding, the “heat tint” or discoloration must be removed for passivation and aesthetic purposes.

Offering mobile laser cleaning services to welding shops and fabrication plants is a steady income stream. Lasers can clean the weld seam area faster than grinding wheels and wire brushes, and they provide a more consistent surface profile. This application is critical in industries ranging from pipeline construction to stainless steel food tank manufacturing.

7. Historic Monument and Stone Conservation

Restoring historical monuments requires a delicate touch. The “patina” of age is often desired, but black crusts from pollution and biological growth must be removed. Lasers are the tool of choice for conservators because the intensity can be dialed down to clean stone without micro-fracturing the surface.

To make money with a laser cleaning machine in this sector, you generally need to demonstrate a high level of control and care. However, projects involving the restoration of statues, cathedral facades, and war memorials are often funded by government grants and pay very well. The contactless nature of the laser ensures that intricate carvings are preserved.

8. Specialized Manufacturing: Brake Pads and Transmissions

Beyond general cleaning, lasers play a crucial role in the manufacturing line itself. For example, in the automotive supply chain, brake pads and transmission parts require specific surface treatments to ensure proper bonding and friction characteristics.

High-volume manufacturers utilize specialized equipment such as the Automatic Transmission Brake pads Laser Cleaning Equipment. This is not a service you would offer with a handheld unit, but rather an industrial integration opportunity. By consulting for factories and installing automated laser cleaning stations, you can streamline their production. This highlights the importance of partnering with a manufacturer that offers “Automatic Customized Solutions” to tailor the machine to the specific production line.

To successfully execute any of the business models listed above, the quality of your equipment is the single most critical factor. Reliability, power stability, and after-sales support can make or break your operation. This is why industry professionals turn to Super Fast Laser Technology Co.,Ltd.

Headquartered in Shenzhen, Super Fast Laser Technology Co.,Ltd. is currently the first domestic manufacturer in their region to focus exclusively on the R&D, production, and sales of laser cleaning machines. Unlike generalist trading companies, they possess their own R&D team and production factory, placing them in a leading position in the laser cleaning field.

Why Choose Super Fast Laser Technology?

The company focuses on high-tech laser application fields, with the primary purpose of pursuing product specialization. They provide professional laser cleaning, automatic equipment, software, and a full set of laser cleaning solutions to strive for the most professional high-end technical services.

Their product portfolio covers the full spectrum of applications discussed in this article:

- Handheld Laser Cleaning Machine: Perfect for mobile service providers focusing on rust removal, graffiti, and automotive restoration.

- 6 Axis automatic Mold Laser Cleaning Machine: The ideal solution for B2B contracts with injection molding factories.

- Automatic Transmission Brake pads Laser Cleaning Equipment: specialized machinery for the automotive manufacturing sector.

- Automatic Customized Solution: Tailored engineering for unique industrial requirements.

By sourcing from a manufacturer with deep R&D capabilities, you ensure that your business is built on technology that is durable, efficient, and supported by experts.

The Business Model: Costs vs. ROI

Understanding how to make money with a laser cleaning machine requires a look at the financials. While the initial investment for a high-quality fiber laser (ranging from 1000W to 3000W) can be significant, the operational costs are incredibly low.

Operational Efficiency

Laser cleaners consume electricity but require no consumables like sand, soda, or dry ice. They also have very low maintenance requirements compared to mechanical compressors and blasting pots. This means your gross margin on every hour of labor is significantly higher.

Pricing Your Services

Most laser cleaning service providers charge between $150 and $300 per hour, depending on the complexity of the job and the power of the machine required. For industrial contracts, billing is often done by the project or via a monthly retainer for facility maintenance.

Return on Investment (ROI)

With high hourly rates and low running costs, many operators report breaking even on their machine investment within 6 to 12 months of operation, provided they have a steady stream of clients. The key is marketing the value of the service: the time saved, the lack of mess, and the preservation of the underlying asset.

Summary of Opportunities

| Industry Sector | Primary Application | Ideal Equipment Type | Revenue Potential |

|---|---|---|---|

| Automotive | Rust Removal / Restoration | Handheld Laser Cleaning Machine | High (Consumer/B2B) |

| Industrial Manufacturing | Mold Cleaning | 6 Axis Automatic / Robot Arm | Very High (Recurring Contracts) |

| Marine | Hull De-fouling | High-Power Handheld | High (Seasonal/Niche) |

| Civic/Municipal | Graffiti Removal | Portable/Backpack Laser | Stable (Government Contracts) |

| Production Line | Brake Pads / Transmission | Automatic Specialized Equipment | High (Industrial Sales) |

Frequently Asked Questions

How much training is required to operate a laser cleaning machine?While the machines are user-friendly, proper safety training is essential. Operators must understand focal distances, power settings, and laser safety protocols (such as wearing OD6+ protective eyewear). Companies like Super Fast Laser Technology Co.,Ltd. typically provide training resources with their equipment.

Is laser cleaning safe for all surfaces?Laser cleaning is excellent for metals (steel, aluminum, titanium) and stone. It is generally not used on wood or plastic unless specific low-power settings are used, as the heat can char these materials. Always test a small area first.

Can I really make money with a laser cleaning machine as a side business?Yes. Many operators start with a mobile van setup, offering services on weekends for car restoration or graffiti removal, before scaling up to full-time industrial contracting.

What is the difference between CW (Continuous Wave) and Pulsed lasers?CW lasers are generally faster for heavy rust and paint removal on thick metals but generate more heat. Pulsed lasers are more expensive but offer finer control and less heat input, making them better for delicate molds, thin metals, and historical restoration.