- Ziva@CKlasersz.com

- WeChat:86-13138536413

- 400-168-9906

- 0755 27084852

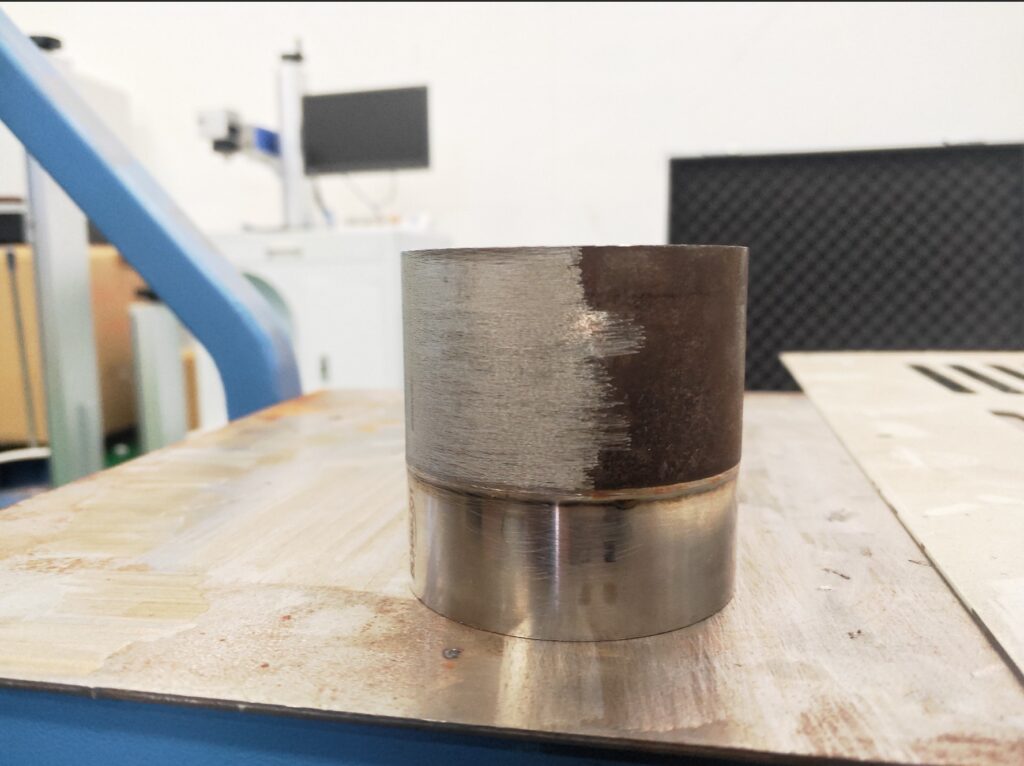

精密机械部件

精密机械部件

1.螺钉和机筒(功能部件)

激光清洁具体应用:

A. 螺杆清洁应用:

螺钉在高温高压下工作,会积累极其顽固的污染物:

碳化层:塑料和橡胶材料在高温下分解,形成坚硬、致密的碳化炭,牢牢附着在螺杆翅片和凹槽上。.

颜料和添加剂沉淀:母料或功能添加剂(如阻燃剂)在金属表面沉淀烧结。.

腐蚀产品:原材料中的腐蚀性成分或设备维护不当造成的锈蚀。.

B. 机筒清洁应用:

根据辊筒功能的不同,污染物也各不相同:

压花滚筒:树脂、颜料、纤维和其他残留物会堵塞图案的细槽。.

涂料桶:干涂料和粘合剂会积聚在表面。.

印刷桶:必须清除油墨、清漆残留物和纸屑等杂质。.

传热桶:会形成水垢和油垢。.

优势尺寸:

A. 非破坏性清洁、基体和涂层保护:这种非接触、零磨损工艺可彻底清除杂质,同时完美保护精确的螺杆几何形状和昂贵的涂层(如铬和聚四氟乙烯)或滚筒表面的精细图案。.

B.彻底清洁,无盲点:激光束可以灵活地照射到复杂的轮廓,如螺杆根部和侧翼,以及转鼓单元的每个角落,实现无盲点清洁。.

C. 延长部件寿命:通过防止化学腐蚀、物理磨损和热变形,昂贵的螺杆和滚筒的使用寿命可延长数倍,从而带来极高的投资回报。.

推荐模式

未找到结果。.