- Ziva@CKlasersz.com

- WeChat:86-13138536413

- 400-168-9906

- 0755 27084852

10 Beste Laser-Reinigungsmaschine für rostfreien Stahl

10 Beste Laser-Reinigungsmaschine für rostfreien Stahl

Stainless steel remains one of the most widely used materials in modern industry due to its corrosion resistance and aesthetic appeal. However, maintaining its pristine surface requires advanced solutions. In 2026, the Best Laser-Reinigungsanlage for stainless steel has become an essential tool for manufacturers seeking to remove oxidation, weld heat tints, and surface oils without using abrasive chemicals or physical scrubbing.

This guide provides a comprehensive review of the top 10 laser cleaning systems available this year, specifically engineered for the unique reflective properties and precision requirements of stainless steel.

In This Guide

- 1. Why Laser Cleaning for Stainless Steel?

- 2. Featured: Super Fast Laser Solutions

- 3. Top 10 Best Laser Cleaning Machines 2026

- 4. Technical Specifications & Power Comparison

- 5. Buying Guide: Finding the Right Power Level

- 6. Summary Comparison Table

- 7. Frequently Asked Questions (FAQs)

- 8. References & Standards

1. Why Laser Cleaning for Stainless Steel?

Stainless steel is prized for its passivation layer, a thin chromium oxide film that prevents rust. Traditional cleaning methods like sandblasting or chemical pickling can damage this delicate layer or leave behind residues that cause pitting over time. The Best laser cleaning machine for stainless steel solves this by using focused light to vaporize contaminants while leaving the base metal intact.

In 2026, the industry has shifted toward fiber laser technology. These machines offer high efficiency and are particularly effective at removing weld discoloration (heat tint), carbonized oils, and protective film adhesives. Because the process is non-contact, there is no mechanical wear on the stainless steel surface, preserving the original grain or polished finish.

2. Featured: Super Fast Laser Industry Solutions

For high-volume industrial applications, specific specialized equipment is required to maintain production speed. We highlight two revolutionary systems from the Super Fast Laser lineup:

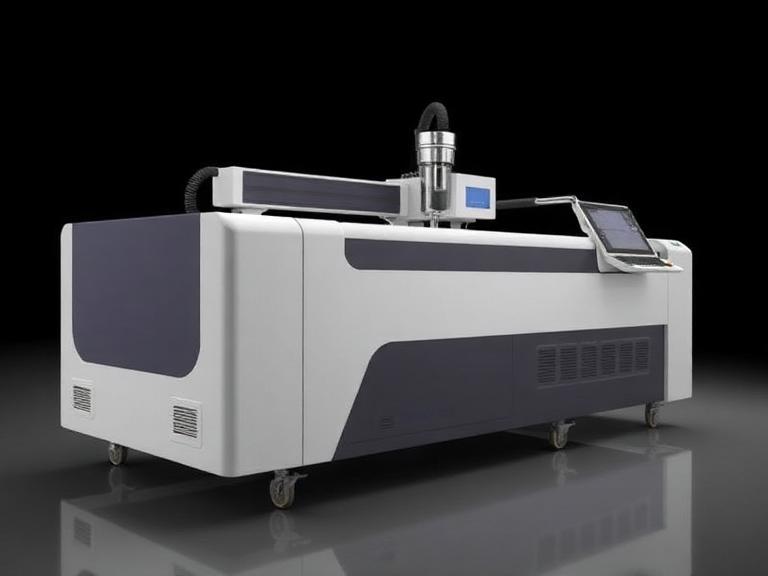

Super Fast Laser Tire Mold Online Cleaning Equipment

This tire mold online cleaning equipment is a new generation of high-tech, non-contact cleaning equipment that does not damage the component substrate, requires no consumables, is energy-efficient, environmentally friendly, and noiseless. It efficiently removes oil, stains, vulcanizer residues, high-temperature rubber residues, rust, oxide layers, and other surface contaminants from molds. It meets the cleaning requirements of complex shapes and precise positioning in industrial processing, achieving higher cleaning results and lower overall production costs.

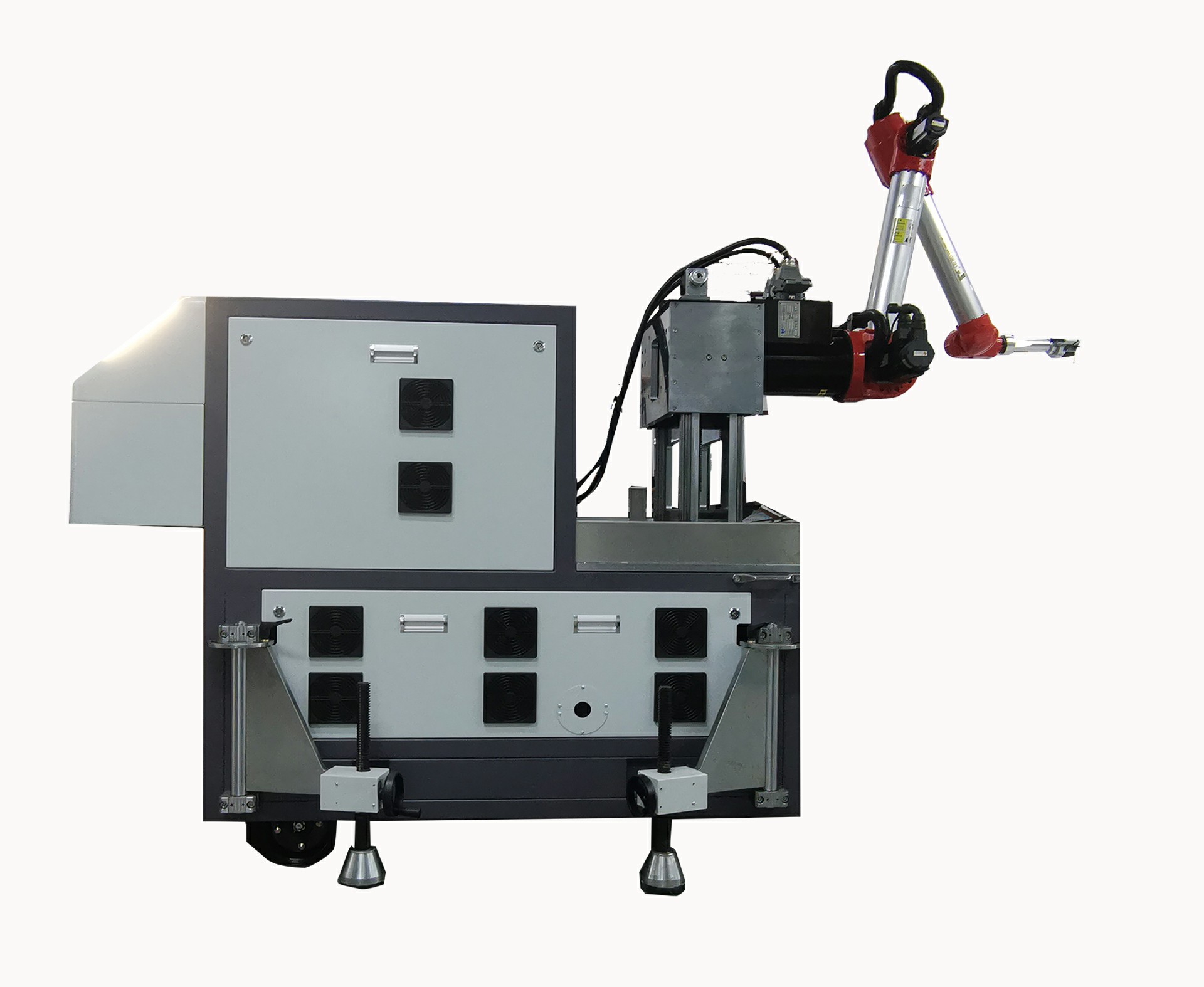

Super Fast Laser Automatic Robot Cleaning Machine

The core of the robotic automatic cleaning machine is used in irregular, high-precision, multi-batch parts cleaning scenarios. Through the flexible movement of the robotic arm, it can achieve precise cleaning of complex structures such as workpiece surfaces, inner cavities, and gaps. This is particularly effective for stainless steel assemblies used in the aerospace and medical sectors where human consistency may vary.

3. Top 10 Best Laser Cleaning Machines 2026

1. CleanLASER CL 1000 (The Industrial Standard)

As a global leader, CleanLASER’s CL 1000 is often cited as the Best laser cleaning machine for stainless steel in heavy-duty environments. Its “Adaptive Pulse” AI technology automatically adjusts the laser frequency based on the surface reflectivity, ensuring that polished stainless steel is never over-exposed or discolored by heat.

2. IPG Photonics LightWELD XC (Portable Multi-Tool)

IPG has revolutionized the market with a handheld unit that can both weld and clean. For stainless steel fabricators, this 2-in-1 capability is invaluable. You can clean the weld joint area before joining and then immediately switch modes to remove the heat tint post-weld.

3. Super Fast Laser Robotic System (Automation Leader)

As mentioned in our featured section, this system is the gold standard for automated lines. It uses a high-precision robotic arm to navigate 3D stainless steel structures, making it the top choice for automotive exhaust and food-grade tank manufacturing.

4. Trumpf TruClean Eco (Efficiency King)

Trumpf remains a powerhouse in German engineering. The TruClean Eco is designed with heat recovery technology, reducing energy consumption by 30%. It is highly recommended for facilities running 24/7 operations where electricity costs are a primary concern.

5. Laserax LXQ-500 (Niche Specialist)

The LXQ series from Laserax is optimized for the electric vehicle (EV) sector. It excels at cleaning stainless steel battery casings and busbars. Its UltraShield technology ensures that no debris is left behind that could cause electrical shorts.

6. Han’s Laser HL-AMBIDEXX (The Volume Choice)

Han’s Laser offers a dual-head system that allows for simultaneous cleaning of two sides of a stainless steel plate. This significantly increases throughput in large-scale architectural stainless steel production.

7. STYLECNC LC1500 (Best Value for Small Business)

For smaller workshops, the LC1500 provides an affordable entry point. It uses a 1500W continuous wave (CW) laser source that is highly effective for removing light rust and paint from stainless steel sheets without a massive upfront investment.

8. Blue Elephant Handheld 100W (Precision Pulse)

Not every job requires 2000W of power. For delicate stainless steel medical instruments or fine jewelry, this 100W pulsed laser offers surgical precision. It removes microscopic contaminants without heating the bulk material.

9. YiHai Laser YH-ECO360 (Eco-Conscious Choice)

YiHai has introduced a solar-compatible off-grid cleaner. It is perfect for cleaning stainless steel structures in remote locations, such as water treatment facilities or offshore oil rigs, where traditional power sources are limited.

10. Adapt Laser AL-150 (Heritage Restoration)

The AL-150 is the preferred choice for historical restoration. If you are cleaning architectural stainless steel on a landmark building, its precise pulse duration control ensures you remove years of soot and pollution without altering the historic patina.

4. Technical Specifications & Power Comparison

When selecting the Best laser cleaning machine for stainless steel, technical parameters like wavelength and pulse frequency are critical. Stainless steel reflects about 60% to 70% of 1064nm light at low power, so the machine must have enough peak power to break the surface tension of the contaminant layer.

| Technical Attribute | Pulsed Laser (100W-500W) | Continuous Wave (1kW-3kW) |

|---|---|---|

| Application | Precision, Thin Materials | Starker Rost, dicke Beschichtungen |

| Heat Impact | Minimal (Cold Process) | Moderate (Thermal Process) |

| Cleaning Speed | Slower / High Quality | Very Fast / Industrial |

| Finish Quality | Pristine / Mirror-like | Matte / Satin |

5. Buying Guide: Finding the Right Power Level

Choosing the Best laser cleaning machine for stainless steel requires a balance between speed and surface integrity. If your goal is to remove weld discoloration on 304 stainless steel, a 200W to 500W pulsed laser is ideal as it provides a bright, clean finish. If you are cleaning large stainless steel storage tanks with heavy industrial buildup, a 2000W continuous wave laser will be more cost-effective due to its higher square-meter-per-hour rate.

Consider the “Scan Width” as well. For irregular shapes, you need a machine like the Super Fast Laser Robotic System that can adjust its scan pattern from linear to circular or square to match the workpiece geometry.

6. Summary Comparison Table

| Model | Primary Use | Price Range (USD) | Leistungsstufe |

|---|---|---|---|

| CleanLASER CL 1000 | High-End Industrial | $40,000 – $60,000 | 1000W Pulse |

| IPG LightWELD | Weld/Clean Combo | $15,000 – $25,000 | 1500W CW |

| Super Fast Automatic | Robotic/Complex Parts | Custom Quote | 500W – 2kW |

| STYLECNC LC1500 | Budget/General Metal | $4,000 – $8,000 | 1500W CW |

| Laserax LXQ-500 | Automotive/EV Batteries | $30,000 – $50,000 | 500W Pulse |

7. Frequently Asked Questions (FAQs)

Will laser cleaning cause my stainless steel to rust later?

No. In fact, laser cleaning can actually improve corrosion resistance. It removes surface impurities that can lead to localized corrosion. Many laser systems are designed to promote the immediate reformation of the chromium oxide passivation layer.

Can I use the same machine for stainless steel and aluminum?

Yes, most machines on this list are versatile. However, because aluminum is more reflective than stainless steel, you may need to adjust the frequency and power settings to avoid “back-reflection” damage to the laser source. High-end machines like those from Superschneller Laser include safety sensors to prevent this.

Do I need special training to operate these machines?

Laser safety is paramount. While the operation is intuitive, operators must wear specific laser safety goggles (OD 6+ or higher for 1064nm). Robotic systems are safer as they are usually enclosed in a Class 1 safety housing.

What are the maintenance requirements?

Laser cleaning is a non-contact process, meaning there is almost no mechanical wear. The primary maintenance involves cleaning the protective lens every few hours of use and ensuring the cooling system (water or air) is functioning correctly.